CONTAINMENTS SYSTEMS (ISOLATOR)

In Pharmaceutical industry isolation technology is either used to protect the product from the operator (ex: aseptic processes), or protect the operator from the product (ex: potent product handling).

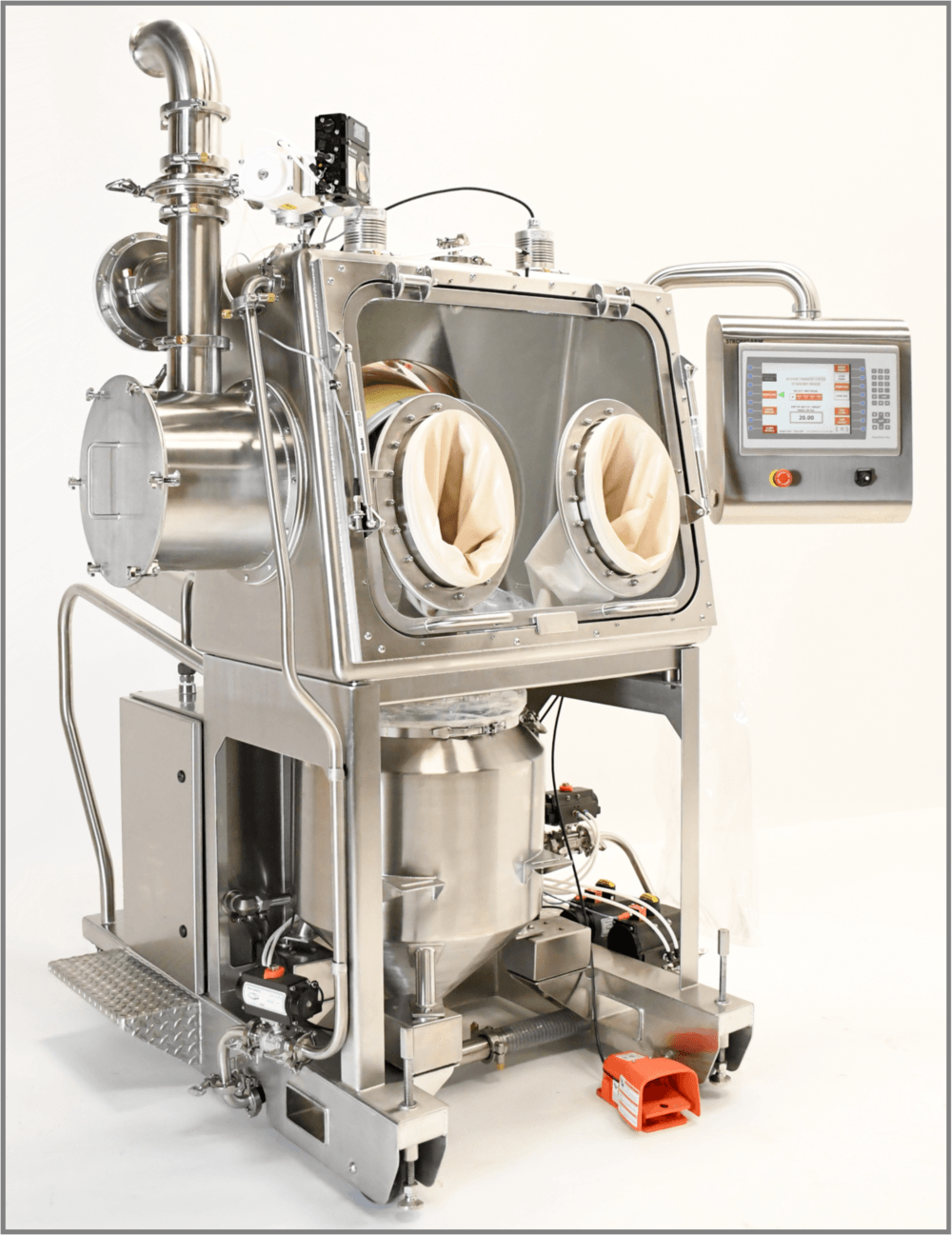

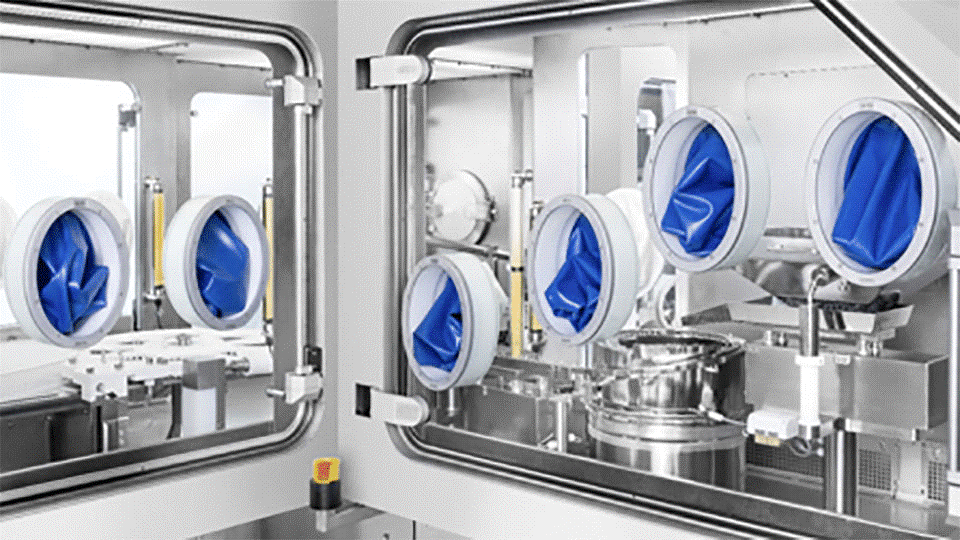

Isolator is a leak tight enclosure which acts as a physical barrier and provides a work-space, which is separated from the surrounding environment.

It usually consists of a shell, viewing window, glove/sleeve assemblies, supply and exhaust filters, light (s), gauge (s), Input and Output openings (equipment door air-locks, Rapid Transfer Ports (RTPs), etc.), and various other penetrations. There are of isolators:

1. Closed Isolators – Isolators operated as closed systems do not exchange unfiltered air or contaminants with adjacent environments. Their ability to operate without per-sonnel access to the critical zone makes isolators capable of levels of separation be-tween the internal and external environment unattainable with other technologies. Be-cause the effectiveness of this separation, closed isolators are ideally suited for appli-cation in the preparation of sterile and/or toxic material. Aseptic and Containment iso-lators are two types of closed isolators.

2. Open Isolators – Open isolators differ from closed isolators in that they are de-signed to allow for the continuous or semi-continuous egress of materials during op-eration, while maintaining a level of protection over the internal environment. Open isolators are decontaminated while closed, and then opened during manufacturing. Open isolators typically are used for the aseptic filling of finished pharmaceuticals.

The intent of isolators is to create an airtight barrier or enclosure around a piece of equipment or process which provides an absolute separation between the operator and product. The operator can perform tasks through half-suits or glove ports. Isola-tors provide a specific environment inside the isolator using HEPA filters. The envi-ronment can be positive pressure or negative, can have humidity control and oxygen control.

.jpg)

Isolator Types

- Positive Pressure Isolator for Aseptic Sterile Compactor and filling lines

- API Formulation Isolator

- Barrier Isolator

- IPQC Isolator

- QC Isolator

- Milling & Sieving Isolator

- Pack off Isolator

- Pharmaceutical Containment Isolators

- Pharmaceutical Aseptic Isolators

- Dispensing Isolators

- Transfer Isolators

- Sub-division and Weighing Isolators

- Cell Therapy – Cell Culture Isolators

- R&D Isolators and Class III Biosafety Cabinets

- Reactor and Charging Isolators

- Off-Loading Isolators

- Cytotoxic Compounding Containment Units

- Milling & Blending Isolators

- Sterility Testing Isolator

- OSD Isolator

- R&D Isolator

- Granulation Isolator

- Injectable Isolator

- Glove box

- Flexible Isolator

- Vacuum Tray Drying Isolators

- Reactor Charging Isolator

- ANFD Isolator

- VTD Drying Isolator

- Milling and Sieving Isolator

- Weighing & Pack-off Isolator

- Auto Filter Cleaning Isolator

Applications

- Pharmaceuticals

- Chemical

- Medical

- Food manufacturing

- Food industry

- Forensics

- Microbiology and Tissue culture lab

- Entomology

- Veterinary and seed sciences

- Pathology

Types of Isolator

Check Out Some Different Types Of Isolators

Get In Touch

Address

1/50 Horizon Industrial Park, At: Por on Vadodara - Mumbai NH No.8, Vaoddara, Gujarat. India - 391210

Phone

+91 9558686999